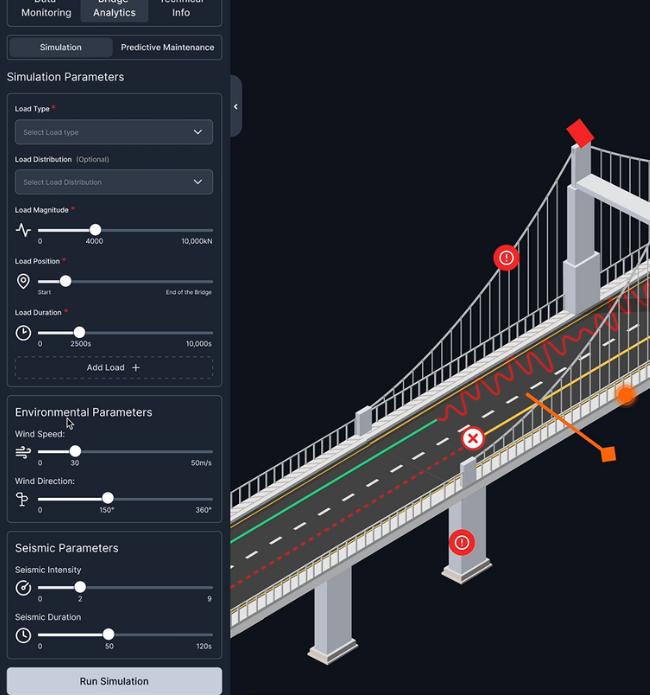

With traditional methods of monitoring and maintenance so limited, teams from TYLin and Dar collaborated to develop cutting-edge bridge monitoring technology.

The digital twin integrates 3D modeling, IoT sensors, artificial intelligence, and advanced analytics to analyze a bridge’s behavior in real time.

It assesses stresses and repair needs, as well as predicting future problems, suggesting pre-emptive repairs and reinforcement strategies before issues arise.